Description

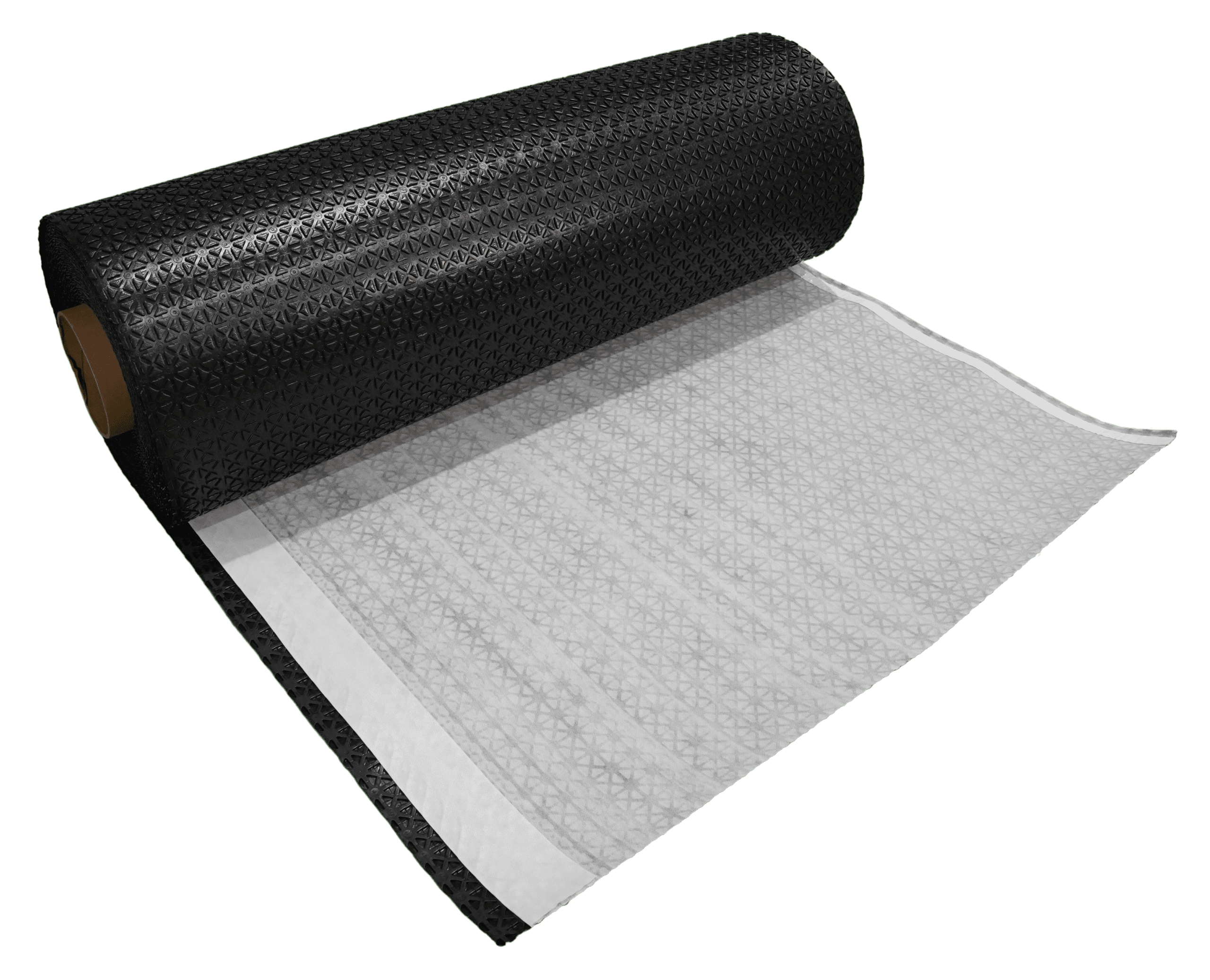

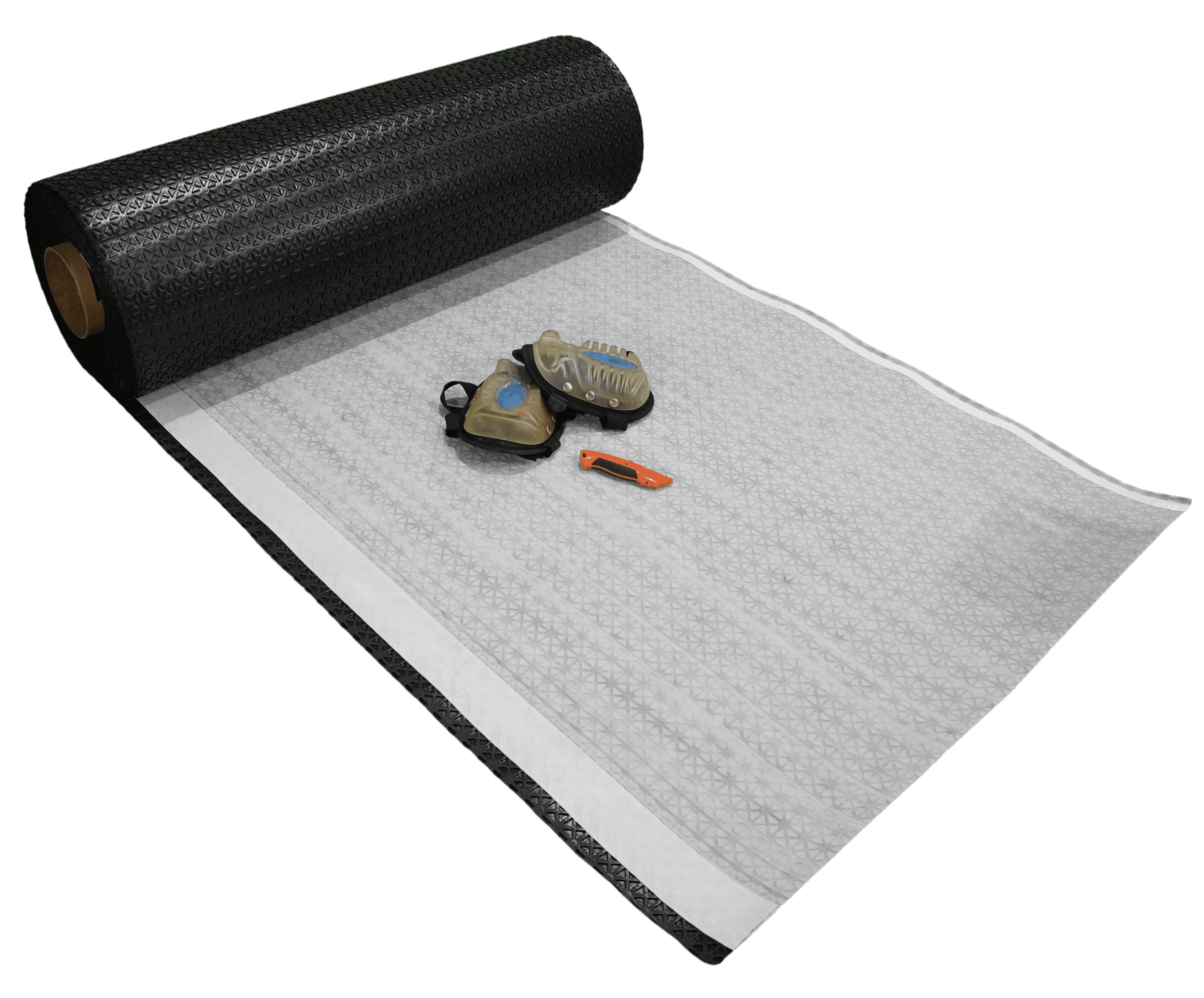

Treadstone® R1 Sound Mat utilizes our new Q-Seam Technology. This advancement provides a robust and monolithic foundation for the underlayment and ensures proper installation. Underlayments are typically installed with seams abutted and taped together, but this method often leads to small gaps being left after taping. These unsupported gaps will push down as the underlayment is applied, providing a point of direct contact between the underlayment and the sub-floor assembly. These valleys destroy acoustical performance and can lead to premature floor failure. Treadstone® R1 Sound Mat’s innovative Q- Seam Technology addresses this issue by ensuring each seam is tightly overlapped and fastened during installation.

Features/Benefits

- With ¾” Treadstone® underlayment, the system can reduce impact noise (IIC) up to 12db in wood framed assemblies.

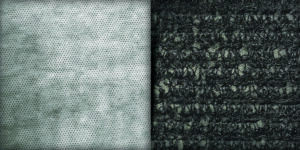

- Polypropylene barrier fabric•1/8” thick, total system thickness as thin as 7/8”.

- Industry leading compression resistance

- UL listed in over 100 floor ceiling designs

- Installed by a network of technically trained licensed dealers