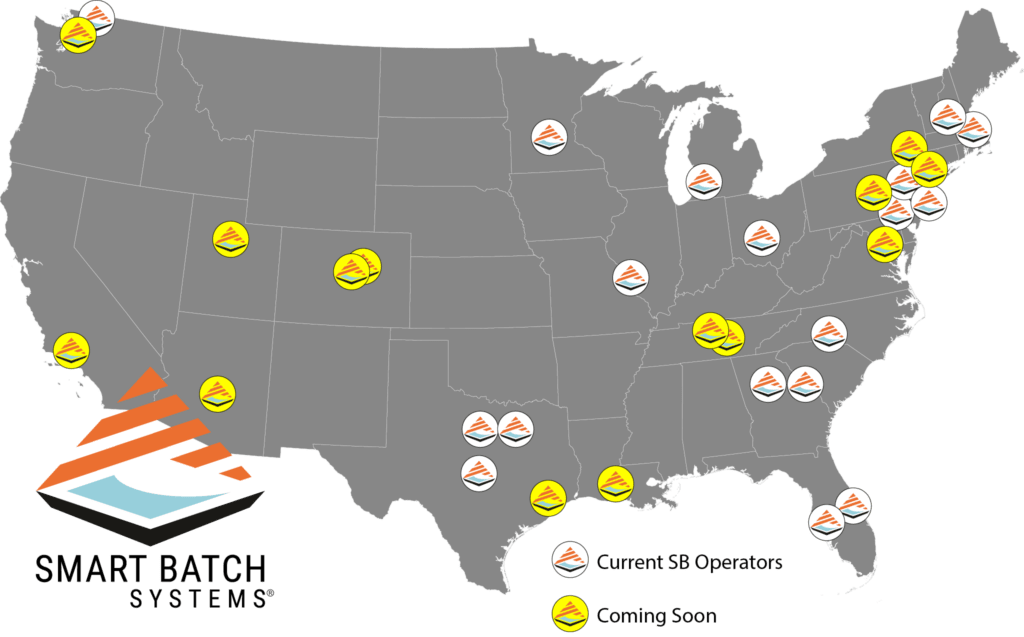

Smart Batch® Batch Mixer speeds up production, increases productivity and delivers accuracy that can be proven with detailed reporting by utilizing automation and bulk materials.

"*" indicates required fields

Smart Bach Systems is an equipment manufacturer that is dedicated to making mixing and pouring of cementitious liquids more accurately than any other method. Smart Batch wraps engineering function around technology to deliver daily logs ensuring that Smart Batch owners can accurately manage their business. Smart Batch GC1 will weigh each raw material before batching to ensure standards are met or exceeded. Smart Batch is also dedicated to safety and engineers its products to remove dust and other harmful airborne contaminates from the jobsite.

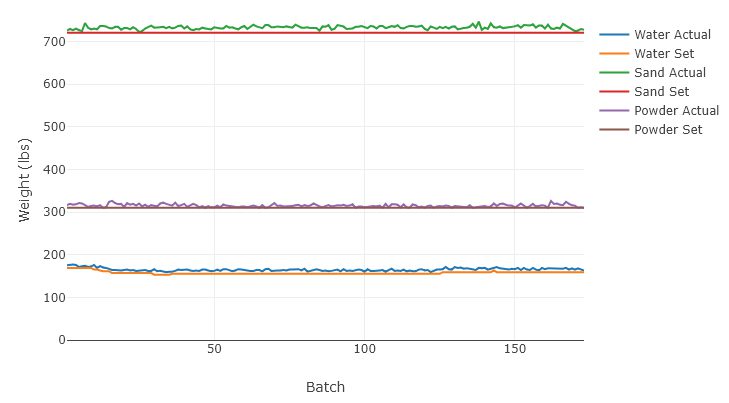

Purpose built to address issues commonly encountered when delivering poured gypsum underlayments and levelers, the GC-1 delivers the accuracy and reliability required to keep your operation profitable. Fully automated batching by ingredient weight virtually eliminates over watering and sanding on a pour, and the recorded data and wirelessly transmitted reports provide an accurate record of your days work.

The utilization of bulk materials, touch-screen operation and elevated work-platform increase safety, eliminate lifting and turning, andreduce the number of dust events by over 97%, resulting in a safer and cleaner work environment. These efficiencies deliver higher production (up to 40,000 ft2 a day) and allow your crews to focus on delivering a finished product that meets or exceeds spec on every pour.